Description

Product Overview

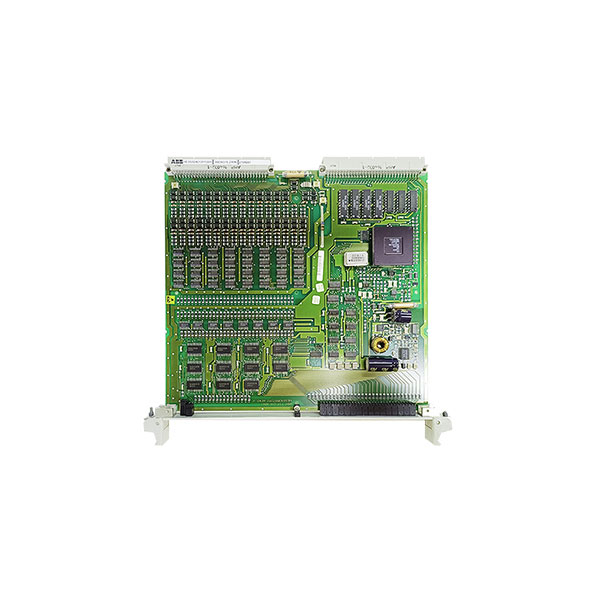

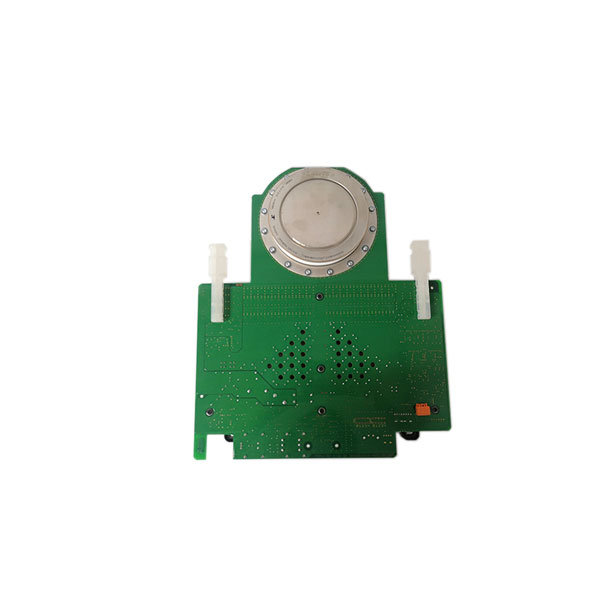

The ABB CI522A 3BSE018283R1 is a specific model of Analog Input Module from ABB’s Advant Controller 800M (AC 800M) family, part of the renowned Symphony Plus and Harmony Control Systems. It is a high-density, intelligent analog input module designed for demanding process control applications. The module acts as the primary interface between field-mounted analog sensors/transmitters (providing 4-20 mA, 0-20 mA, 0-10V, 0-5V, etc., signals) and the AC 800M controller. It converts these analog signals into high-resolution digital values for processing by the controller’s control logic, enabling monitoring and closed-loop control of process variables like pressure, temperature, level, and flow. The part number CI522A is the base model identifier, while 3BSE018283R1 is ABB’s unique, detailed Material Ordering Code (MOC) that specifies the exact hardware version, revision, and ordering configuration.

The value of the CI522A module lies in its high precision, channel-to-channel isolation, and seamless integration within the ABB distributed control system (DCS) architecture. It is engineered for maximum reliability in critical industrial environments, offering features like hot-swap capability, comprehensive diagnostics, and compliance with stringent industry certifications. For system engineers designing or maintaining ABB Symphony/Harmony based control systems, the CI522A is a core component for reliably acquiring analog process data. Its specific MOC ensures compatibility with the controller’s backplane, power requirements, and configuration software, guaranteeing reliable performance and simplified spare parts management.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|---|---|

|

Product Model

|

ABB CI522A 3BSE018283R1

|

|

Manufacturer

|

ABB (ASEA Brown Boveri)

|

|

Product Series

|

Advant Controller 800M (AC 800M) I/O Module

|

|

Primary Function

|

16-Channel Analog Input Module

|

Module Specifications

-

Channels: 16 analog input channels, individually configurable.

-

Input Types (Software Configurable per Channel):

-

Current: 4-20 mA, 0-20 mA

-

Voltage: 0-10V, ±10V, 0-5V, 1-5V

-

Resistance: For RTD simulation and other resistive sources (specific range depends on configuration).

-

-

Resolution: 16-bit analog-to-digital (A/D) conversion, ensuring high measurement precision.

-

Isolation: Channel-to-channel isolation and group isolation from the controller’s internal electronics. This prevents ground loops and protects the system from field-side electrical noise or faults.

-

Input Impedance: High impedance for voltage inputs; typically 250Ω burden for 4-20mA current inputs.

-

Accuracy: Typically ±0.1% of full-scale range or better, depending on input type and range.

-

Update Rate: Configurable scanning time per channel group, optimized for process control speeds.

-

Power Supply: Powered directly from the AC 800M controller’s baseplate/backplane. Typically +24V DC.Electrical & Environmental

-

Operating Temperature: 0 to 60°C (32 to 140°F)

-

Storage Temperature: -40 to 85°C (-40 to 185°F)

-

Relative Humidity: 5% to 95%, non-condensing

-

Certifications: Compliant with major international standards for electromagnetic compatibility (EMC) and safety (e.g., CE, cULus, ATEX/IECEx for specific variants).System Integration

-

Compatible Controllers: ABB AC 800M controllers (e.g., PM861, PM864, PM865).

-

Mounting: Installs directly into the I/O slots of the AC 800M rack or a remote I/O unit (S800 I/O).

-

Field Connection: Via pluggable, screw-terminal or spring-clamp Field Wiring Modules (FWM) or TBs (e.g., TA527, TB511), which connect to the module’s front connector.

Key Features and Advantages

Key Features and Advantages

High-Density Precision in a Rugged Package: The CI522A packs 16 configurable analog input channels into a single module slot, maximizing I/O density and reducing cabinet footprint. Its 16-bit resolution and high accuracy ensure that even small process changes are detected, providing the controller with the highest quality data for precise control.

Enhanced System Integrity and Diagnostics: The module provides individual channel-to-channel isolation, a critical feature that prevents a fault on one channel (e.g., a short to power) from affecting the signals on adjacent channels or damaging the controller. Comprehensive onboard diagnostics continuously monitor module health, signal validity (e.g., open wire detection on 4-20mA loops), and calibration status, reporting faults to the control system for predictive maintenance.

Seamless DCS Integration and Hot-Swap Capability: As a native component of the ABB Symphony/Harmony ecosystem, the CI522A is configured, commissioned, and diagnosed entirely within the Control Builder M (CBM) or Control Builder Plus engineering tools. The hardware is automatically recognized, and its parameters are managed in the system database. The hot-swap capability allows for module replacement without powering down the controller or stopping the process, a vital feature for maintaining high plant availability.

Application Areas

The CI522A module is a fundamental building block for process data acquisition in ABB DCS-controlled plants across all major process industries. It is used wherever analog process signals need to be reliably and accurately brought into the control system.

Typical applications include:

-

Oil & Gas, Petrochemical, and Refining: Connecting pressure transmitters, temperature transmitters (4-20mA from field-mounted temperature transmitters), level transmitters, and control valve positioners.

-

Power Generation (Thermal & Nuclear): Acquiring analog signals from critical plant instrumentation for boiler control, turbine monitoring, and feedwater systems.

-

Pulp & Paper, Chemical, and Pharmaceutical: Interfacing with a vast array of analog sensors for process variable monitoring in batch and continuous processes.

-

Water and Wastewater Treatment: Reading signals from pH/ORP/conductivity analyzers, flow meters, and pump discharge pressure transmitters.

Related Products

-

ABB AC 800M Controller: The main processor unit (e.g., PM861, PM864) that houses the CI522A module in its rack.

-

Baseplate / Backplane: The mounting and communication backbone for the I/O modules (e.g., for S800 I/O).

-

Field Wiring Module (FWM) / Terminal Block: The interface unit that provides the screw terminals for field wiring connection to the CI522A (e.g., TA527 or TB511 for analog inputs). This is a required accessory for field wiring.

-

Power Supply Module: Provides system power to the controller and I/O rack.

-

Communication Modules: For integrating the I/O into the control network (e.g., CI854, CI855 for Profibus, etc.).

-

Engineering Software: ABB Control Builder M Professional for hardware configuration, application programming, and commissioning.

Reviews

There are no reviews yet.